Industrial Maintenance Services

Industrial Service

Turnkey Projects

In our many years as suppliers of industrial maintenance services we have come across to diagnose inefficient industrial machine maintenance processes (i.e. maintenance and corrections carried out by manufacturing operators who lack of in-depth problem solving procedures) that lead to an exponential increase of system failure incidence by increasing the number of breakdowns in a time line.

Industrial maintenance must be carried out by a specialised industrial maintenance technician in close collaboration with the operators who are most familiar with the operation of the installations and electronic equipment.

Your production facility operations are backed up with INDUFIT MACHINE, and our quality industrial machine maintenance services, with base in London and offered across UK and abroad.

Our industrial maintenance service is about diagnosing, planning, executing, commissioning and preventing against breakdowns, strongly recommended if your priority is to cater your business operations needs with rapid response at any stage.

At Indufit Machine we have assumed as a rule that for being an Industrial maintenance company we must see the logistics as an essential part of the service, so as from in-site routinary inspections and functioning assessments, and all the way through the commissioning of procurement processes, our industrial maintenance services team has the control to support your industrial installation and al the associated infrastructure.

More than 40 years of experience, and a long-time gained trust from our clients speak for our industrial machinery services leading the sector, and our industrial maintenance service engineers who are there to provide you a reliable support with expertise, and knowledge.

Our industrial maintenance services allow us to maximise your equipment and installations life cycles, looking to increase its performance, and for instance, the level of highest amortisation for them.

Got already your internal industrial machine maintenance procedures for years?

As many businesses have their own internal procedures application, with more or less resources, results are proven to be maximised if hiring industrial maintenance services from an outsourcing company with full time dedication and expertise. Here are just few advantages for which Indufit Machine, is your best option when it comes to industrial maintenance services:

– The reduction of costs, since you pay for effective hours worked, we optimise the corrective and preventive maintenance deployed time, we reduce the consumption of spare parts and consumable expenditure increasing availability and therefore production.

– Assured availability of experience, knowledge and technical resources in maintenance engineering.

– Flexibility in the management of human resources, avoiding employment conflict problems with personnel and with industrial maintenance companies that do not provide integral services.

– Your increase in production revenues versus production related expenditures.

Mounting & Assembly of Industrial Machinery – Disassembly of Industrial Machinery – Moving and Transport of Industrial Machinery – Industrial installations – Machinery Installations and Removal – Industrial Machinery Repair – Start-up of Industrial Machines – Industrial Machinery Movers – Retrofit – Machinery Relocation – Heavy-duty Machinery Transportation – Preventive and Corrective Maintenance.

Maintenance Service Plan

Maintenance Service Plan

Support planMaintenance service: Doesn’t matter if it is a root-cause analysis to a major problem or simply a routinary procedure to check in on your CNC, at INDUFIT MACHINE our core objective is to have an everyday functioning report so your production system is monitored against unpredicted failures. It is all based on your business needs. Let’s tailor your production facilities a plan today, contact us.

To receive a quote tailored to your company’s needs, please contact Indufit Machine

Types of Machine Maintenance

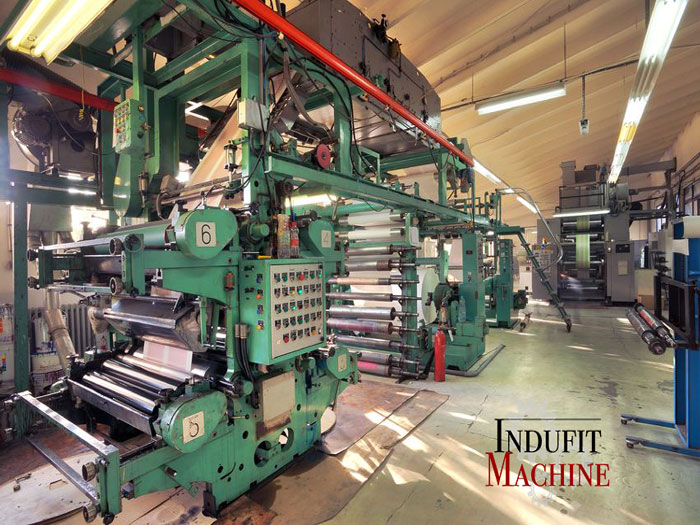

Electrical Industrial Maintenance

Our electrical industrial maintenance services aims to provide coverage to your business operations needs by assisting in the preventive analysis, monitoring and routinary tasks for the optimum functioning of your production line electrical components, meaning that from solenoid valves to sensors, from heating sensors to motors your production system can have an extended life cycle with us.

Our industrial electrical services are based in London, but offered across the UK and abroad. We could help your business to have an updated and constantly monitored status of your industrial electrical installations, and from there take important decisions on whether replacement or repair is the suitable solution.

By planning inspection routines based and tailored for the electrical – mechanical infrastructure at your production facilities we assume the role of your company giving it detailed evaluation and going beyond than just replacing damaged parts.

Our Industrial Maintenance services team, formed by engineers and skilled electricians, are aware that on eventual failures some equipment or Industrial Machines are more critical than others for the continuity of your production operations, hence their practices are focused on looking up to help you control significantly the failure incidence on electrical Panels to frequency converters, DC regulators, automatons, power supplies. We can account for complete overhauls on electrical arrangements of industrial machinery too.

Contact us now for more information on our Industrial Electrical maintenance service.

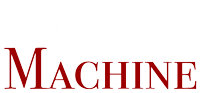

Mechanical Industrial Maintenance

At Indufit Machine our approach for Mechanical Maintenance involves the combination of thousands of Man-Hours of experience throughout years in the sector, constant update and learning, on time response with the appropriate logistics. Our state of the art resources are available 24 – 7 to help your business either solve uncalled events in your production facility’s mechanical installations or set out long terms mechanical maintenance service coverage plans to upkeep your production operations with the least risk of halts.

Our efficient pool of industrial mechanical maintenance engineers and technicians are ready always, to troubleshoot your mechanical systems at your production lines, they are London based but deployable nationwide, and globally.

If you have any doubts on when scheduling a maintenance stop, they will advise you on the type of inspections and tests that must be carried out to achieve optimum and efficient mechanical and industrial maintenance for your machine.

The coordination of a mechanical maintenance stop requires a very high level of organisation, since the cost, duration and efficiency of the work are important for companies with industrial machinery.

We supply specialised personnel in sufficient quantity, together with the specific resources and tools to carry out industrial mechanical maintenance tasks. For more info contact us now.

We perform Predictive, Preventive and Corrective Electrical and Mechanical Maintenance

Predictive maintenance involves a physical variable relation to the wear condition of machines and is based on the measurement, tracking and monitoring of parameters and operating conditions of equipment, machines and installations for carrying out an specific work performance. In this regard, at Indufit Machine, our definition of an industrial mechanical maintenance service handles a series of pre-alarm and performance data values providing the necessary information, on when, how, where the resources –of course, including your production precious time- need to be deployed for maintenance.

Our Predictive, Preventive, and Corrective maintenance service for electrical and mechanical installations and systems offer different approaches to help your business operations optimise cost and times, so we high light the following:

- Enable us to work focused on the pre-alarm values, planning just the necessary time and resources.

- The processed data provide us enough information to act on time, so any premature failure on your system, either electrical or mechanical, is detected and avoided to reach a later state that could be lead your operations to an unpredicted collapse.

- Prevent your production plans from unscheduled downtimes as the pre-alarm will provide us with the information necessary to outline a plan for repair or replacement.

- Avoid unnecessary spare parts inventory, hence storage associated costs, as with sufficient time you will know which components from your system will need to be replaced.

With our electromechanical preventive maintenance service we anticipate breakdowns so your production operations will avoid major problems as full systems repairs or expensive unnecessary replacements or stock of spare parts, especially in heavy duty machinery subject to a lot of wear and mechanical-led stresses such in electric motors, conveyor belts, rotating machines, textiles, automotive and CNC machinery. purchase of spare parts is restricted to the very moment it is necessary, reducing stock costs for companies.

Corrective maintenance nature is to deal with the failure after its occurrence, or even a full intervention to the system after some failure signal is found to eventually lead to a halt.

At Indufit Machine unexpected breakdowns must be premised under as short as possible repair procedures, accounting for immediate and special tooling, skilled manpower and experience in these logistics. Depending on the breakdown, the corrective maintenance would normally bring lower financial expenditures than the financial losses generated during an emergency halt at your production facility.

We are an industrial maintenance company, well skilled to handle mechanical and electrical maintenance services, contact us and find out our services catalog available for your industrial operations.

Being preventive is a norm. Your business operations should rely in our services.

We additionally offer electrical and mechanical preventive maintenance services to avoid as far as possible unnecessary collapse of your industrial machines or production systems. But just in case, we have fast and efficient solutions, and the experience to handle it minding the minimum intervention or avoidance of a halt in your production processes.

Our predictive, preventive and corrective maintenance services are based in London, but will suit your needs throughout the UK, and even abroad. Visit our emergency repair services time responses to find out more.

Industrial Service around the World

Mechanical and Electrical Assembly

Specialist Technical Advice

Ask for your quote today

If You Have Any Questions or Technical Problems, Please Do Not Hesitate To Contact Us.